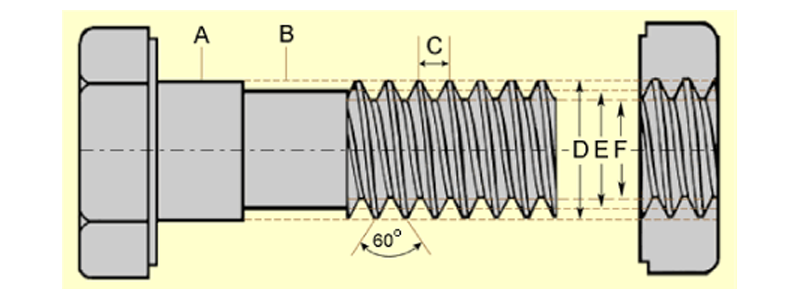

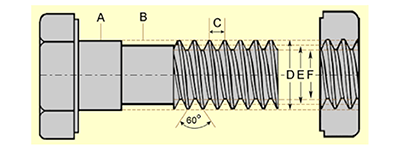

A. FULL DIAMETER SHANK: Equal to major diameter of thread. Produced by cut thread or by roll thread on extruded blank. Characteristic of machine bolts and cap screws.

B. UNDERSIZED SHANK: Equal approximately to pitch diameter of thread. Produced by roll threading a non-extruded blank. Characteristic of machine screws.

C. PITCH: The distance from a point on the screw thread to a corresponding point on the next thread measured parallel on the axis.

D. MAJOR DIAMETER: The largest diameter of a screw thread.

E. PITCH DIAMETER: The simple, effective diameter of screw thread. Approximately half way between the major and minor diameters.

F. MINOR DIAMETER: The smallest diameter of a screw thread.

LEAD: The distance a screw thread advances axially in one turn.

CUT THREAD: Threads are cut or chased; the unthreaded portion of shank will be equal to major diameter of thread.

ROLLED THREAD: Threads are cold formed by squeezing the blank between reciprocating serrated dies. This acts to increase the major diameter of the thread over and above the diameter of unthreaded shank (if any), unless an extruded blank is used.

Classes of thread are distinguished from each other by the amounts of tolerance and allowance specified. External threads or bolts are designated with the suffix "A"; internal or nut threads with "B".

B. UNDERSIZED SHANK: Equal approximately to pitch diameter of thread. Produced by roll threading a non-extruded blank. Characteristic of machine screws.

CLASSES 1A and 1B: For work of rough commercial quality where loose fit for spin-on-assembly is desirable.

CLASSES 2A and 2B: The recognized standard for normal production of the great bulk of commercial bolts, nuts and screws.

CLASSES 3A and 3B: Used where a closed fit between mating parts for high quality work is required.

CLASS 4: A theoretical rather than practical class, now obsolete.

CLASS 5: For a wrench fit. Used principally for studs and their mating tapped holes. A force fit requiring the application of high torque for semi-permanent assembly.

Disclaimer: The dimensions listed are for reference only. Sizes not listed may be available off the shelf or can be manufactured to customer requirements.